CI Testing Lab Locations

CI Silicon Valley Testing Lab

CI Los Angeles Testing Lab - click to view lab equipment

CI North Carolina Testing Lab - click to view lab equipment

Military Standard Testing

CI Testing Labs offer knowledgeable and experienced military standard testing services. Military standard testing evaluates product durability in response to typical environmental challenges and usage. Products that pass military standard testing are proven to withstand the impacts, vibrations, humidity levels, and temperature shifts encountered through typical use, transport, and storage.

These standards are the result of the ongoing partnership between the U.S. Army, Navy, and Air Force. MIL-STD testing methods involve environmental testing of equipment according to typical conditions experienced during a lifecycle. Highly trained and experienced engineers are available to assist with military standard testing projects. Commonly performed MIL-STD testing methods are listed below.

Military Standard Testing Types

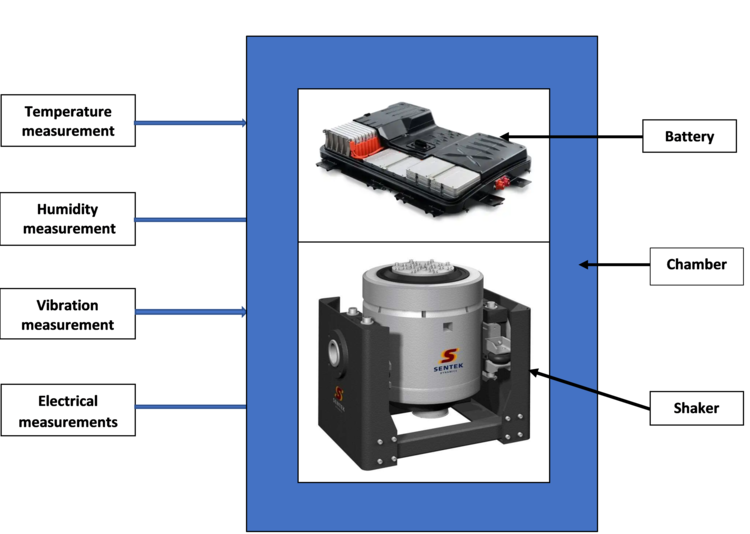

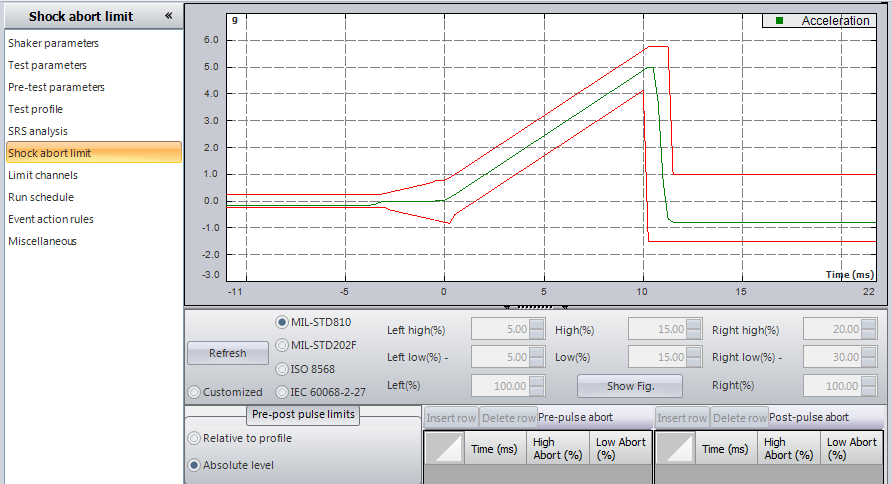

MIL-STD-810— the “Department of Defense Test Method Standard for Environmental Engineering Considerations and Laboratory Tests” — covers most of the environmental factors encountered during the use of military equipment in all stages of its service life. MIL-STD-810 testing involves replicating these conditions in a controlled laboratory environment through the use of temperature, humidity, shock, vibration, acceleration, and other simulation equipment.

| Method 501.6 | High Temperature |

|---|---|

| Method 502.6 | Low Temperature |

| Method 503.6 | Temperature Shock |

| Method 505.6 | Solar Radiation |

| Method 507.6 | Humidity |

| Method 509.4 | Salt Fog (Spray/Corrosion) |

| Method 514.7 | Vibration |

| Method 516.7 | Shock |

| Method 520.4 | Temperature, Humidity, Vibration and Altitude |

| Method 528.1 | Mechanical Vibrations of Shipboard Equipment |

| MIL-STD-202 – Test Method Standard Electronic and Electrical Component Parts | |

|---|---|

| Method 101 | Salt Atmosphere (Corrosion) |

| Method 103 | Humidity (Steady State) |

| Method 106 | Moisture Resistance |

| Method 107 | Thermal Shock |

| Method 108 | Life (at Elevated Temperature) |

In recognition of the detrimental effects of combinations of temperature, humidity, vibration and input electrical power on electrical and electro-mechanical components with regard to safety, integrity, and performance during ground and flight operations, MIL-STD-810H, has been released with Method 520.5 added to cover the testing of components in combined environments. Testing in combined environments may induce failures that would not be exhibited during individual environment testing. New to this test method is the addition of input electrical power as an environment; to include voltage/frequency variations, and transients (if applicable) which are inherent to the system. While it is virtually impossible to replicate the complex mix of environments which can be seen during transport, storage, operation, and maintenance, the intent is to apply representative combinations of stresses to the device under test to determine performance and capabilities.

Reliability Testing Services

CI Testing Labs provides a wide array of reliability testing services to military contractors across the country, including:

Failure analysis

Functional test plan development

HALT/HASS plan development

MTBF calculation

Requirement development