Applying the ASAM ODS Data Format in Crystal Instruments Products

Download PDF | © Copyright Crystal Instruments 2016, All Rights Reserved.

Introduction

The Crystal Instruments’ CoCo-80 is the first hand held data acquisition device to incorporate the ASAM ODS data format. This format was initially developed in the automotive industry to improve the portability of data between hardware and software platforms. It is now used by a majority of the world’s automotive manufacturers and suppliers. This paper describes the ASAM ODS data format and how it is implemented in the Crystal Instruments product line.

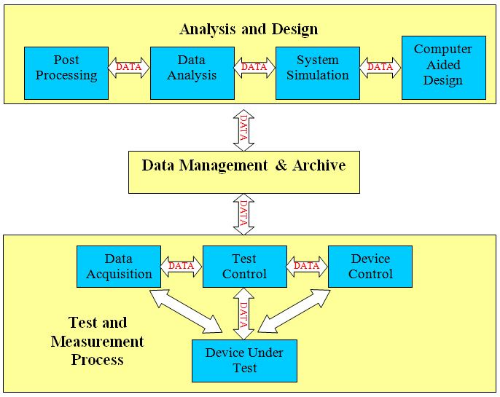

Exchanging data between different hardware and software platforms has always been a challenge in the test and measurement industry. Data typically moves from one platform such as a data acquisition device to another such as a personal computer or a data server. It also is used by various different software tools. For example Figure 1 shows a typical test and measurement process with a device under test, data acquisition and device and test controls. Test data is saved in a data management/archival system and then used in analysis and design tools. At each phase of the process data must be shared between platforms with no loss of data.

Figure 1. Typical test and measurement process includes many phases and requires data portability between all stages.

Difficulties arise when the data format developed by one system vendor is not understood by another, or when data is spread across several different files and the relationship between the files is lost. Typically the solution has been that software vendors provide translation tools that convert their proprietary format into some “universal data format” or into the proprietary format of another vendor. This requires cooperation between many different vendors and is difficult to manage. The process is further complicated when software versions are updated or older data formats are no longer supported.

The reason that sharing data between platforms is so difficult is that vendors design their data format to meet a number of different objectives. For example a data file may include meta information about the device under test, the test hardware, the test protocol, etc. The file may include one long array of one dimensional data such as acceleration versus time, or a multidimensional table of data such as spectra versus time.

When a data file includes a large quantity of information such as sound recordings then the data must be saved in a compact format to conserve storage space. As vendors continually add functionality to their products, data formats change over time. Therefore it is not surprising that the data formats differ dramatically between any two vendors.

The Universal File Format

One effort to address these difficulties was the development of the Universal File formats in the late 1960s. The formats were originally developed as 80 character (card image), ASCII records that occur in a specific order according to each UF format. As computer files became routinely available, single UF formats were concatentated into computer file structures. Later, a hybrid UF file structure (UF Dataset 58 Binary) was developed for experimental data that allowed data to be stored in a more efficient binary format.

Before the introduction of ASAM ODS, the use of the Universal File Format as a defacto “standard” has been of great value to the experimental dynamics (vibration and acoustic) community, particularly in the area of modal analysis. Both users and vendors have benefited from this defacto standard. However the UF format is a static format in that it requires data to be recorded in a predefined format and does not allow the format to vary from the fixed standard. Many new test and measurement tools require a more flexible date format making the UF format obsolete.

Association for Standardization of Automation and Measuring Systems (ASAM)

As data acquisition, analysis and modeling software has matured and become a more integral part of the product development cycle the need for a more modern universal data format has emerged.

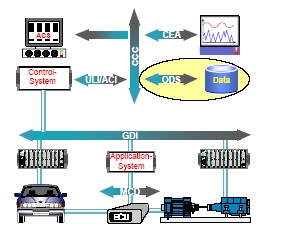

The first effort to provide a new data exchange structure comes from ASAM (Association for Standardization of Automation and Measuring Systems). This group was originally formed in 1991 as an initiative of German automobile manufacturers. Today, the Association has over 60 members reflecting a strong influence from the US and European automobile industry, including manufacturers, parts suppliers and experimental data acquisition vendors (General Motors, Daimler- Chrysler, Porsche, Volvo, BMW, Delphi Automotive, LMS, and MTS to name a few). ASAM is coordinating a wide range of standards that will affect application software and, in particular, integration of applications and peripheral devices. The figure below shows the different components within ASAM that allow integration of all phases of the test and measurement process.

Figure 2. The ASAM standard includes many components related to the test and measurement process.

The experimental data exchange portion of the standards falls under the ASAM Open Data Service (ODS) activity and intends to define a generic data model, data interfaces and data exchange syntax and format. The goal of the ASAM-ODS activity is to provide an easy-to-use, text based exchange format (ASAM Transport Format, ATF) to exchange data, including associated meta information, between different operating systems and different hardware platforms.

Originally ASAM ODS used an ASCII based format named ATF/CLA. However recently the use of eXtensible Markup Language (XML) was added to the standard. The CoCo-80 has adopted the ATF/XML format of ASAM-ODS. XML is an easy to use and well known data structure that is regarded to be a long term tool. Using XML files for data exchange and data archiving was introduced for several purposes.

It provides more detailed automatic verification of an ATF/XML file than is possible with ATF/CLA. XML-Schema is an XML-based description for the content of an XML file and this description can be processed by automatic tools which are worldwide available.

As ATF/CLA does, also ATF/XML provides model data on the same file that contains the data (respectively links to the data). This guarantees consistency between model (meta information) and data and ensures that data being exchanged or archived are always understood correctly.

A header section allows information about version, base model and originating system;

XML syntax is able to transport references in a more explicit way, e.g. using pointers, which makes references verifiable by automatic tools;

Meta information is enclosed in tags, this makes the file well-formed and thus allows easy checks.

The ATF/XML file is a logical file which may consist of one or more physical files.

Connectors between existing universal packages like EXCEL®, MATLAB®, etc. and the ODS data store will be offered.

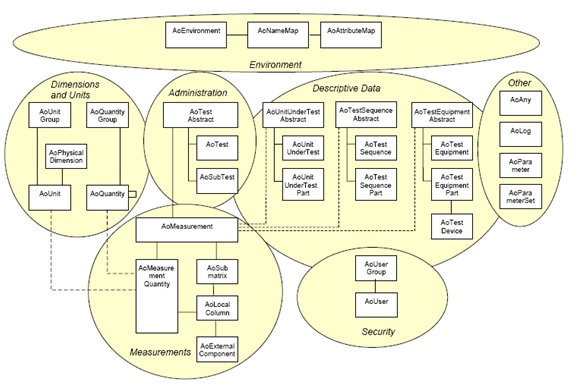

Figure 3. ASAM Data structure.

The overall structure of an ASAM-ODS ATF/XML file is described in the following figure. It includes meta information, or information pertaining to the data, including environment, dimensions and units, administration, description and security. All meta information is stored together with the actual data in most cases. The standard also allows meta information to be stored in a separate file when the data file is very large and requires a more compact binary data format.

The careful design of the ASAM/ODS data format with the open architecture that is hierarchical results in a new universal file format that improves the portability of measurement data. This allows data to be shared between platforms and software ensuring data and all data attributes are maintained throughout the process.

Figure 4. The CoCo-80 and the Engineering Data Management System allow the user to view all meta information within the ASAM ODS ATF/XML data file as well as the original data.