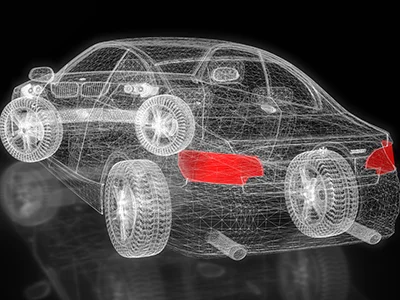

Automotive Industry

Automotive applications span a broad range of technology from design through product quality auditing. Manufacturers are under enormous competitive pressure to provide increasingly improved quality, safety, mileage, luxury, and economy. This places a heavy burden on automotive NVH Engineers to accomplish more, faster. Fast-paced development cycles in the modern car, truck, and coach industry demand the use of functionally flexible measurement equipment with friendly intuitive operation to unravel the dynamic and acoustic mysteries of the modern vehicle.

Data Acquisition and Analysis

In-vehicle data recording and analysis

Dynamometer testing and chassis tuning

Drive-line balance and stability tests

Component and body-in-white modal tests

Pass-by acoustic monitoring

NVH and whole body vibration

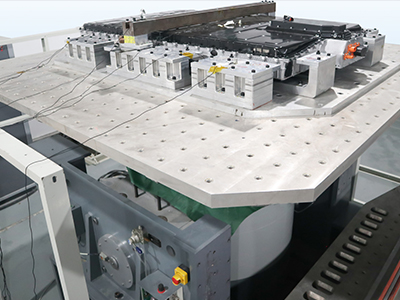

Vibration Test Control

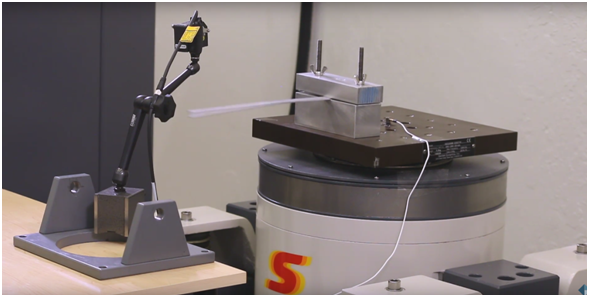

Component shake tests with road-recorded loads

Material and component fatigue evaluations

Component durability testing

Transport simulation, time waveform replication

Finite element model verification

Multi-drive with multi-shaker test

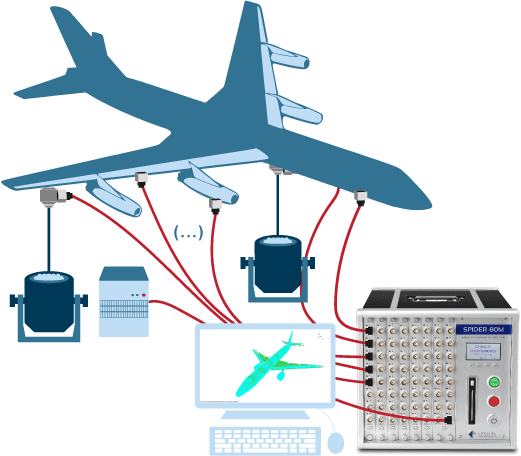

Aerospace Industry

Development of space vehicles, satellites, fixed wing aircraft and helicopters is a technologically leading business calling for the most advanced analysis and control instrumentation. Design verification of hardware and mathematical models is an all important activity. The high cost of aerospace structures and the uniqueness of prototypes demand the most careful conduct of every controlled vibration investigation. Probing the edges of the unknown calls for extreme dynamic range and analysis flexibility in the measurement hardware employed.

Data Acquisition and Analysis

Wind tunnel dynamic studies

High channel reliable data recording

Flight stress and vibration recording

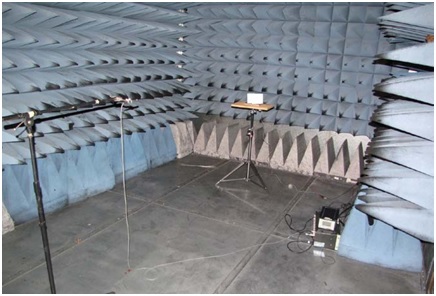

External and internal acoustical surveys

Engine durability testing

Vibration Test Control

Sine, RSTD, Random, SoR

Durability tests using recorded flight data

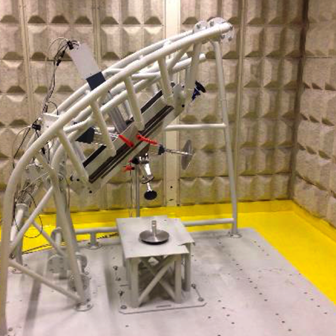

Launch and separation simulation

Payload dynamic qualification

Proof-of-performance component stress screening

MIL-Spec testing

Education & Academia

Producing first-rate engineers is a daunting responsibility. More and more, experimental skill and experience with technologically advanced instrumentation is demanded by industry. Today’s engineers need to be both analytically competent and experimentally capable. Leading universities have broadened their curricula and softened the edge between electrical and mechanical studies to serve this need. Economic constraints place a premium on cost-effective instruments that can perform a variety of tasks by changing software. Flexible licensing that allows hardware modules to be used separately around the campus or to be brought together to form a large channel count system is now essential.

Data Acquisition and Analysis

Introduction to digital signal processing

Observing vibration and acoustic phenomena

Characterizing analog electronic circuits

Rotating machinery analysis

Modal testing and analysis

Real-time digital filters with configurable signal analysis

Vibration Test Control

Introduction to electro-dynamic shakers

Introduction to hydraulic shakers

Concepts in shaker control

Swept-sine testing

Random testing

Shock testing

Products for the Educational Field

Military Organizations

The military forces of the United States design and acquire a variety of specialized hardware and systems for use on land, in the air and at sea. Military acquisitions range from miniaturized electronics packages to surface ships and aircraft. All of this material is subjected to rigid incoming inspection and testing in accordance with military specifications.

Data Acquisition and Analysis

Ship and submarine silencing

Helicopter and jet vibration

Vehicle dynamic strain recording

Flight/road test recording

Engine/driveline analysis

Route-based vibration data collection

Vibration Control

Random shake testing

Swept-sine shake testing

Classical shock testing

Drop-table shock testing

Pyrotechnic shock tests and SRS

Flight and launch simulations

Products for the Military (Crystal Instruments products are designed with advanced security features for military applications.)

Testing Labs

Commercial testing laboratories provide capital facilities and in-depth testing expertise to industry. They often represent the least expensive means to qualify a product and prove its compliance to a broad range of specifications and codes. Leading test laboratories have an extensive range of shaker and shock test facilities supported by the most modern control and analysis electronics available.

Data Acquisition and Analysis

Stress and vibration recording

CE requirement testing

Product vibration surveys

Component modal studies

Servomechanism verification

Circuit performance tests

Vibration Control

Product durability testing

Random, SoR, RoR shaker testing

Swept-sine, RSTD shake testing

Shock-on-shaker testing

Seismic testing and earthquake simulation

Combined thermal and stress testing

Applications for Testing Labs

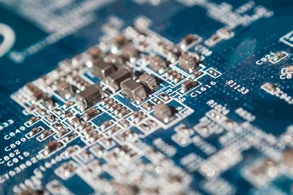

Electronics Industry

The electronics industry spans and affects every aspect of human life. It is an extremely broad industry ranging from military hardware to personal entertainment products and everything in between. Personal computers, tablets and smart cellular telephones are part of everyone’s life and of many industrial systems. Chronometers, radar, sonar and GPS let us navigate our world precisely. Radios, television and the internet keep us informed and communicating. All of these things have analog components to be understood and packaging concepts to be qualified.

Data Acquisition and Analysis

Analog circuit bench testing

Analog network analysis and tuning

Characterizing component background noise

Measuring gain, phase and linearity

Magnetic field frequency response

Verifying system poles and zeros

Automated production test

Vibration Control

Highly accelerated stress screening (HASS)

Highly accelerated life-testing (HALT)

Package design verification

Spec-qualifying a module, chassis or rack

Environmental simulations; packaging tests

Drop-testing shock response analysis

Sine and dwell test for qualification

Applications for the Electronics Industry

Products for the Electronics Industry