Ruby Wireless Sensor

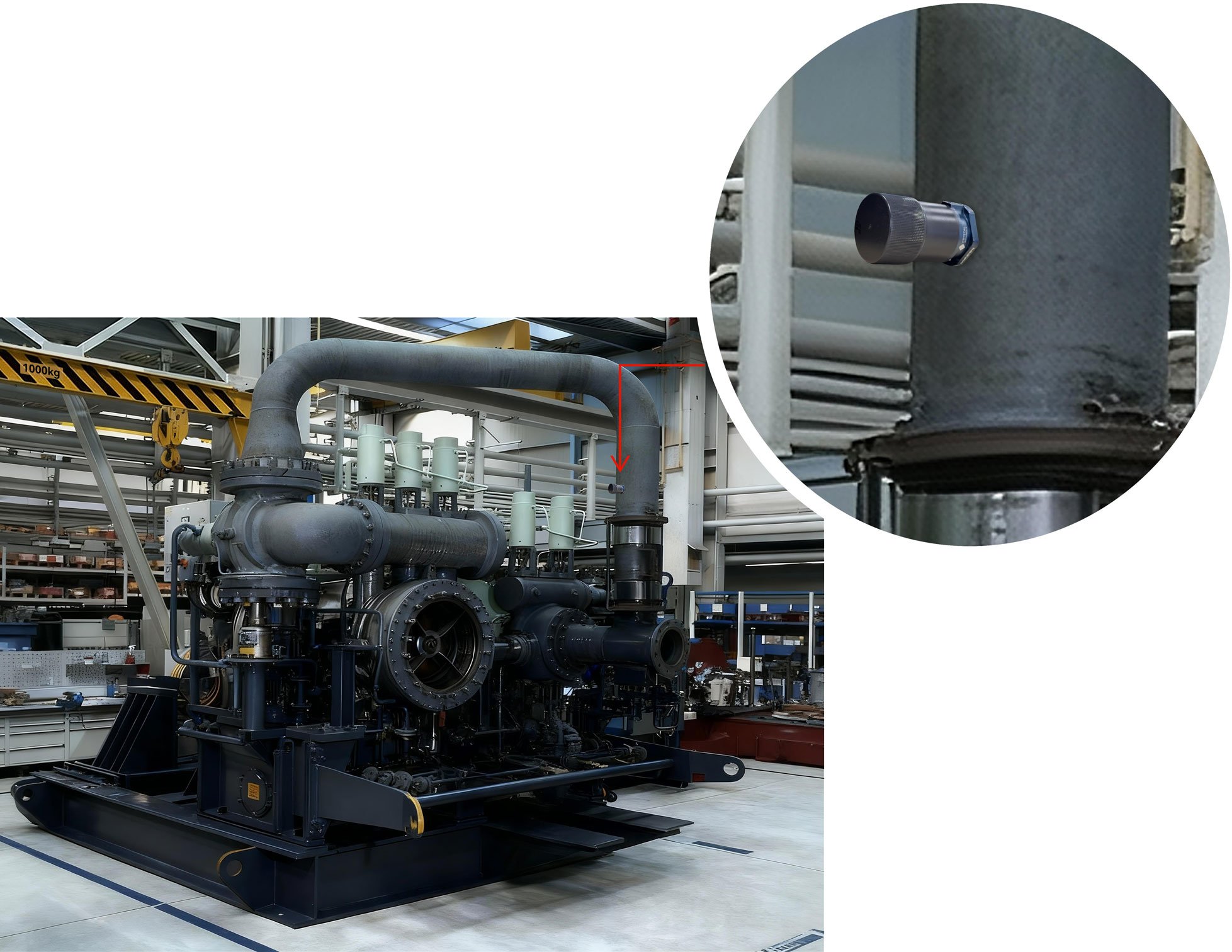

Machine Vibration Monitoring

The Ruby wireless sensor is a battery powered, ultra-compact device that measures vibration signals in acceleration quantity on mechanical structures.

Internally, it consists of a 3-axis sensor component, an ARM processor, 24-bit ADC (Analog to Digital Converter), flash memory storage and a battery.

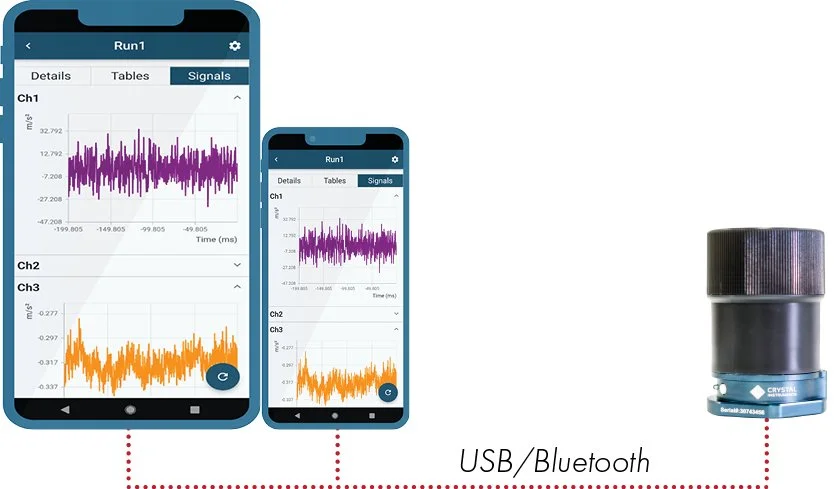

Its interface features an RF transceiver that supports the ISA-100 wireless protocol, Bluetooth connectivity, and a USB.

Install hundreds of sensors in a factory setting.

Reliable Data Transfer

The ISA-100.11a protocol is built on a mesh network, where small wireless nodes, known as motes, act as both sensors and data relays. These motes form a self-organizing, multi-hop network, ensuring data is transmitted reliably, even in challenging industrial environments.

100’s of Wireless Sensors

In a common machine factory, a few hundred wireless sensors can be installed on different machines. Multiple access points, i.e., gateways, will be installed at optimum locations to cover all the wireless sensors in the area.

2-Year Battery Life

The wireless sensors will usually be in the deep sleep mode. A wireless sensor will consume current at tens of µA level during deep sleep mode. This low-power consumption design allows the sensor to operate using a standard D-type battery for approximately 2 years.

Three hardware platforms:

CoCo-70X - waterproof & dustproof handheld vibration analyzer

Spider front-ends - permanently mounted systems equipped with patented high precision data acquisition technology

Ruby - waterproof & dustproof wireless sensors

Machine monitoring software:

RCM (remote condition monitoring) software is in charge of configuring the Ruby and Spider systems and acquiring data.

VDS (vibration diagnostic system) software processes data using artificial intelligence and a rule-based expert system.

High Precision Measurement in 3-Axis

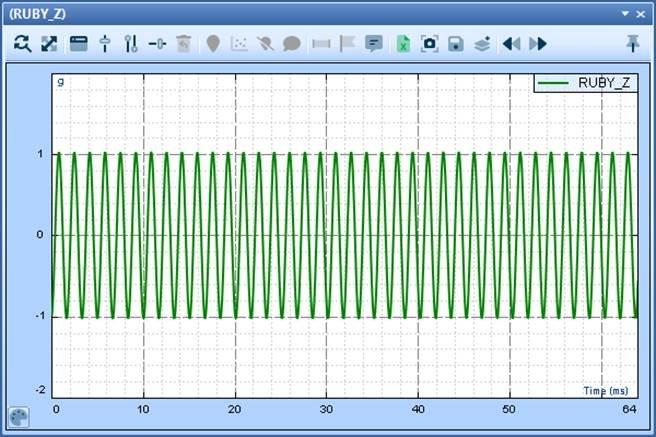

Ruby provides measurements in 3-axis as accurate as common charge vibration or piezoelectric sensor measurements. The frequency range goes up to 6.5 kHz while the tolerance is within +/- 1.0 dB.

Independently Scheduled Measurements

One of Ruby’s key advantages is its ability to take measurements and send wireless transmission on independent schedules. This flexibility significantly enhances battery efficiency. For example, Ruby devices can be configured to take weekly measurements and transmit data once a month. The devices remain in sleep mode most of the time to conserve energy, as illustrated in the above diagram.

Minimize EMI

Some applications restrict the total EMI (electromagnetic interference) generated by sensors and their network. Sensors can be awakened in batches to minimize their EMI impact and placed into transmission mode at different time slots.

Industrial Wireless Networking

ISA-100.11a is an industrial wireless networking standard designed to support reliable and secure communication in industrial automation and control systems. It is particularly popular for wireless sensor networks, offering a self-organizing, multi-hop mesh architecture that enhances reliability, scalability, and real-time data transfer.

Remote Data Recording & Signal Processing

An onboard processor can realize the digital filtering, triggering, data window, FFT, auto-power spectrum and averaging operation. Demodulation spectral analysis is also available. Users can save calculated spectra along with recorded time waveforms into flash memory. These data recording and signal processing tasks can be scheduled through RCM, a PC-based Remote Condition Monitoring software.

Sampling Rates & Data Points

The highest sampling rate of ADC can go up to 16 kHz, which results in an excellent spectrum up to 6.5 kHz. The maximum data points that can be recorded are 62 million. The largest FFT size is 4096, which is sufficient for most of the machine vibration purposes.

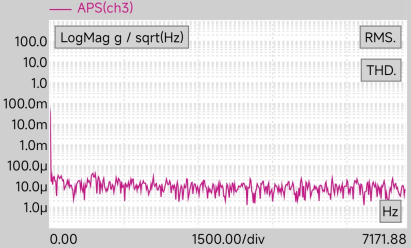

Industry Leading High-Fidelity Device

Ruby is included amongst measurement devices with the highest fidelity offered in this industry. The noise floor of the sensor acceleration measurement is less than 100 μg /√Hz. The Z-axis vibration measurement can go up to 6.5 kHz while the X/Y horizontal axis can go approximately 4 kHz. The tolerance of measurement is typically less than +/- 1.0 dB.

(Released in 1996) CI2250 data acquisition card with handheld DCX computer for machine condition monitoring used by the US Navy

Wireless Vibration Sensor Technology: Benefits, Limitations, and Industrial Applications

This white paper provides an in-depth comparison of three primary methods for machine vibration monitoring: permanently installed wired data acquisition (DAQ) systems with IEPE accelerometers, handheld vibration analyzers, and modern wireless sensor networks. It evaluates each approach based on critical performance metrics such as measurement frequency range, amplitude accuracy, noise floor, and environmental suitability, as well as installation complexity and cost-effectiveness.

Ruby Wireless Sensor Specifications

| Parameters | Description |

|---|---|

| Axis | 3-axis, X, Y, Z |

| Full acceleration range | ±25 g, ±50 g depending on models selected. |

| Sensor usable bandwidth |

|

| Tolerance of Frequency Response for Z axis |

|

| Tolerance of Frequency Response for X or Y axis | 0.5 Hz to 5,000 Hz: +/- 2.0dB |

| Typical Noise Density (RMS) | 20 - 100 μg /√Hz |

| Nonlinearity | 2% |

| Internal A/D resolution | 24 bits |

| RAM | 256 KB |

| Non-volatile memory | 256 MB (store the measurement data) |

| Signal Processing capability | Raw time waveforms, digital filters, data window, FFT spectrum, averaging, simple order extraction, demodulation spectrum required by VDS software |

| Data sampling rate | 16 kHz, 8 kHz, 4 kHz, 2 kHz, 1 kHz, 500 Hz, 250 Hz, 125 Hz |

| Data recording |

|

| Number of FFT lines per block | 450, 900, 1800 |

| FFT block size | 1024, 2048, 4096 |

| Trigger mode |

|

| Data transfer |

|

| Electrical and Communication | |

| USB Interface | USB-OTG, used to set up the sensor, calibration and download the data to a local PC. Can be used as a simple vibration data collector |

| Bluetooth | BLE 5.0 |

| Bluetooth Wireless Range | Typically between 10 to 100 meters indoor |

| Communication protocol | ISA 100.11a, High Performance RF-CMOS 2.4 GHz radio transceiver targeted for IEEE® 802.15.4 |

| Typical ISA Wireless Range | 150 meters sensors to ISA-100 gateways; 100 meters sensor to sensor, line of sight (Actual range depends on obstacles present, gateway antenna type, etc.) |

| Battery type | Replaceable D size 3.6 V |

| Typical battery life of operation | 24 months |

| Electrical isolation | > 108 Ohm |

| Physical | |

| Weight | 365 grams (including battery) |

| Dimensions | 63 mm (bottom, hexagon shape) x 94.2 mm (height) |

| Push buttons | Hold down for 10 seconds to reset: Press once to wake up; Press twice to switch Bluetooth /ISA-100, etc. |

| LED indicator | This LED is visible when the cap is removed. It is used to indicate the status of Bluetooth connection. |

| Mounting | 5/16 -24 female |

| Environmental | |

| Shock and Vibration (operational test) |

|

| Storage Shock tolerance (surviving test) | 800 g / 1 ms |

| EMS conformity | IEC-61326-1, ETSI EN 301 489-1, CISPR22, ETSI EN 301 489-17 |

| Operating Temperature Range | −40 °C to 55 °C (-40 °F to 131 °F) |

| Waterproof Rating | IP 67 (Protected from dust, immersible up to 1 m water) |