Vibration Data Collector Signal Analysis

Download PDF | © Copyright Crystal Instruments 2016, All Rights Reserved.Contents: 1. Section One | 2. Section Two | 3. Section Three | 4. Section Four | 5. Section Five

Section 1

Dynamic Signal Analysis in Vibration Data CollectorThe CoCo-80/90 provides two different user interfaces for Dynamic Signal Analyzer and Vibration Data Collector. The style and settings are different to meet industrial conventions. The user has the choice to enter one of the interfaces when system is powered on. The VDC user interface is specifically designed for fast data collection operation and ease of use. A professional user focused on research and development can open and use the DSA functions instead of that of VDC. This section explains in detail about how the signals are processed when CoCo runs in the VDC mode.

CoCo uses various different technologies of digital signal processing. Among them, the most fundamental and popular technology is based on the Fast Fourier Transform (FFT). The FFT transforms time domain signals into the frequency domain. To perform FFT-based measurements, however, it helps to understand the fundamental issues and computations involved. This Appendix describes some of the basic signal analysis computations, discusses anti-aliasing and acquisition front end for FFT-based signal analysis, explains how to use windowing functions correctly, explains some spectrum computations, and shows you how to use FFT-based functions for some typical measurements. Users should be aware of the subtle differences between a traditional dynamic signal analyzer and a vibration data collector even though they all employ the same signal processing theory.

General Theory of Spectral Analysis

Time Domain Waveform

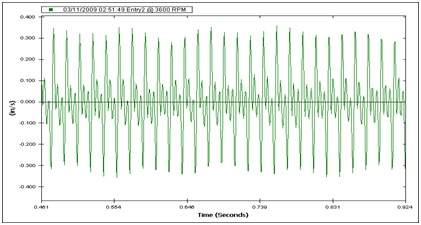

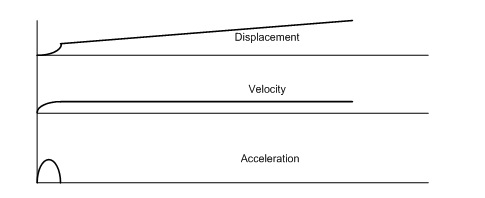

A typical time waveform signal in analog form from the sensor, such as an accelerometer, velocity-meter or displacement probe, could take an appearance like that shown in the following picture.

Figure 1: Time Domain Waveform

In a digital instrument, much the same thing is seen. However, it is necessary in a digital instrument to specify several parameters in order to accurately represent what is truly happening in the analog world. It is important to tell the instrument what sample rate to use, and how many samples to take. In doing this, the following are specified:

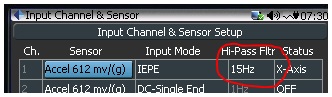

Figure 2: Parameter Setup in CoCo

Measurement Quantity: This field is required to determine what measurement quantity is to be displayed. Even if the sensor is an accelerometer, the CoCo device can integrate it digitally into velocity or displacement.

Fmax: This field defines the maximum frequency of interest for analysis. The sampling rate of the analog/digital (A/D) digitizer will be determined based on this parameter.

Fmin: This is the low frequency cut-off filter that will be applied in the frequency domain for spectral analysis.

Block Size/Spectral Lines: The block size is usually defined in blocks of two (binary) to the power of 10 or more. (Block size of 210 is 1024, 211 is 2048, 212 is 4096, etc.) The block size and Fmax will determine the total time period of each sampling block for frequency analysis. A larger block size for the same frequency band will increase the accuracy of the measurement.

Immediately after the signal is digitized, it will also go through:

- Low pass filters - to eliminate any high frequencies that are not wanted

- High pass filters - to eliminate DC and low frequency noise that are not wanted

Additionally, the integration of the signal provides velocity or displacement from an accelerometer or a displacement from a velocity pickup. Traditional signal analyzers have a drawback of dynamic range in the digital domain and some argue that the analog integration is superior to that of digital. The situation is greatly improved due to the very high dynamic range technology in the CoCo. With more than 130dB dynamic range in the front end, digital integration can achieve excellent accurate results.

The Fourier Transform

CoCo fully utilizes FFT frequency analysis methods and various real time digital filters to analyze measurement signals. The Fourier Transform is used to convert quantities amplitude vs time in the time domain (time waveform) to amplitude vs frequency in the frequency domain (FFT spectrum), usually derived from the Fourier integral of a periodic function when the period grows without limit, often expressed as a Fourier transform pair. In the classical sense, a Fourier transform takes the form of:

Where:

x(t) - continuous time waveform

f - frequency variable

j - complex number

X(f) - Fourier transform of x(t)

As the theory of Jean Baptiste Fourier states: All waveforms, no matter how complex, can be expressed as the sum of sine waves of varying amplitudes, phase, and frequencies. In the case of rotating machinery vibration, this is most certainly true. A machine's time waveform is predominantly the sum of many sine waves of differing amplitudes and frequencies. The challenge is to break down the complex time-waveform into the components from which it is made.

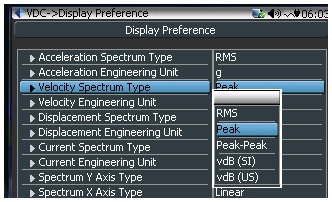

Mathematically the Fourier Transform is defined for all frequencies from negative to positive infinity. However, the spectrum is usually symmetric and it is common to only consider the single-sided spectrum which is the spectrum from zero to positive infinity. For discrete sampled signals, this can be expressed as:

x(k) - samples of time waveform

n - running sample index

N - total number of samples or frame size

k - finite analysis frequency, corresponding to "FFT bin centers"

X(k) - discrete Fourier transform of x(k)

In CoCo, a Radix-2 DIF FFT algorithm is used, which requires that the total number of samples must be a power of 2 (total number of samples in FFT = 2m , where m is an integer).

The Fourier Transform assumes that the time signal is periodic and infinite in duration. When only a portion of a record is analyzed the record must be truncated by a data window to preserve the frequency characteristics. A window can be expressed in either the time domain or in the frequency domain, although the former is more common. To reduce the edge effects, which cause leakage, a window is often given a shape or weighting function. For example, a window can be defined as:

w(t)= g(t) -T/2 < t < T/2

= 0 elsewhere

where g(t) is the window weighting function and T is the window duration.

The data analyzed,x(t) are then given by:

x(t) = w(t) x(t)'

where x(t)' is the original data and x(t) is the data used for spectral analysis.

A window in the time domain is represented by a multiplication and hence, is a convolution in the frequency domain. A convolution can be thought of as a smoothing function. This smoothing can be represented by an effective filter shape of the window; i.e., energy at a frequency in the original data will appear at other frequencies as given by the filter shape. Since time domain windows can be represented as a filter in the frequency domain, the time domain windowing can be accomplished directly in the frequency domain.

Because creating a data window attenuates a portion of the original data, a certain amount of correction has to be made in order to get an un-biased estimation of the spectra. In linear spectral analysis, an Amplitude Correction is applied.

Spectrum

A spectrum in CoCo in VDC mode is calculated based on a few steps including data window, FFT, amplitude scaling and averaging. You can extract the harmonic amplitude by reading the amplitude values at those harmonic frequencies in a spectrum.

To compute the spectrum, the instrument will follow these steps:

Step 1

A window is applied to the time waveform:

x(k) = w(k) x(k)'

Where:

x(k)' is the original data and x(k) is the data used for a Fourier transform.

Step 2

The FFT is applied to x(k) to compute Sx:

Next the "periodogram" method is used to compute the spectra with amplitude correction using Sx.

Step 3

Calculate the "Power Spectrum" Sxx = Sx Sx* / (AmpCorr)2

The factor AmpCorr is calculated based on the data window shape.

Step 4

Apply one of the averaging techniques to the power spectrum Sxx (see below for averaging techniques)

Step 5

Finally, take the square-root of the averaged power spectrum to get final spectrum result.

Section 2

Spectrum Type

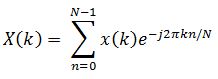

Figure 3: Display Preference Setup

Now we come to a confusing part about the spectrum of a signal. With the same time domain signal, the spectrum can actually be displayed in different values. This is controlled by a parameter, spectrum type, set in the Display Preference on the CoCo.

The motivation of doing so is that people may want to look at different aspect of the spectrum and give different physical interpretation to the original time signals. For example, from the spectrum the user may wants to know the frequency component at 1X rotating speed, represented in its Peak, Peak to Peak or RMS.

To give a practical example, a 100Hz sine wave with roughly 1.0 peak in/s is fed into the CoCo system. The time waveform is shown below:

Figure 4: Time Domain Waveform in CoCo

A very common reading will show a spectrum peak at 100Hz with a peak value reading 1.0208 in in/s (Peak)

Figure 5: FFT Spectrum in CoCo, in/s Peak

If somebody is interested in the RMS value of this frequency component, he can change the spectrum type to RMS, then the display value will be changed to 0.7218.

Figure 6: FFT Spectrum in CoCo, in/s RMS

Similarly, the user can look at Peak to Peak, vDB(SI) and vDB(US) of the spectral peak.

Now let's introduce the concept of dB.

Most often, spectra are shown in the logarithmic unit decibels (dB). Using this unit of measure, it is easy to view wide dynamic ranges; that is, it is easy to see small signal components in the presence of large ones. The decibel is a unit of ratio and is computed as follows.

dB = 10log10 (Power/Pref)

where Power is the measured power and Pref is the reference power.

Use the following equation to compute the ratio in decibels from amplitude values:

dB = 20log10 (Ampl/Aref)

where Ampl is the measured amplitude and Aref is the reference amplitude.

As shown in the preceding equations for power and amplitude, you must supply a reference for a measurement in decibels. This reference then corresponds to the 0 dB level. Different conventions are used for different types of signals.

The vibration velocity level in dB is abbreviated VdB, and is defined as:

The Systeme Internationale, or SI, is the modern replacement for the metric system.

The reference, or "0 dB" level of 10-9 meter per sec is sufficiently small that all our measurements on machines will result in positive dB numbers. This standardized reference level uses the SI, or "metric," system units, but it is not recognized as a standard in the US and other English-speaking countries. (The US Navy and many American industries use a zero dB reference of 10-8 m/sec, making their readings higher than SI readings by 20 dB.)

The VdB is a logarithmic scaling of vibration magnitude, and it allows relative measurements to be easily made. Any increase in level of 6 dB represents a doubling of amplitude, regardless of the initial level. In like manner, any change of 20 dB represents a change in level by a factor of ten. Thus any constant ratio of levels is seen as a certain distance on the scale, regardless of the absolute levels of the measurements. This makes it very easy to evaluate trended vibration spectral data; 6 dB increases always indicate doubling of the magnitudes.

Data Window Selection

Leakage Effect

Windowing of a simple signal, like a sine wave may cause its Fourier transform to have non-zero values (commonly called leakage) at frequencies other than the frequency of this sine. This leakage effect tends to be worst (highest) near sine frequency and least at frequencies farthest from sine frequency. The effect of leakage can easily be depicted in the time domain when a signal is truncated. As shown in the picture, after data windowing, truncation has distorted the time signal significantly, hence causing a distortion in its frequency domain.

Figure 7. Illustration of a non-periodic signal resulting from sampling

If there are two sinusoids, with different frequencies, leakage can interfere with the ability to distinguish them spectrally. If their frequencies are dissimilar, then the leakage interferes when one sinusoid is much smaller in amplitude than the other. That is, its spectral component can be hidden or masked by the leakage from the larger component. But when the frequencies are near each other, the leakage can be sufficient to interfere even when the sinusoids are equal strength; that is, they become undetectable.

There are two possible scenarios in which leakage does not occur. The first is when the whole time capture is long enough to cover the complete duration of the signals. This can occur with short transient signals. For example in a hammer test, if the time capture is long enough it may extend to the point where the signal decays to zero. In this case, a data window is not needed.

The second case is when a periodic signal is sampled at such a sampling rate that is perfectly synchronized with the signal period, so that with a block of capture, an integer number of cycles of the signal are always acquired. For example, if a sine wave has a frequency of 1000Hz and the sampling rate is set to 8000Hz. Each sine cycle would have 8 integer points. If 1024 data points are acquired then 128 complete cycles of the signal are captured. In this case, with no window applied you still can get a leakage-free spectrum.

Figure 8 shows a sine signal at 1000 Hz with no leakage resulting in a sharp spike. Figure 9 shows the spectrum of a 1010 Hz signal with significant leakage resulting in a wide peak. The spectrum has significant energy outside the narrow 1010 Hz frequency. It is said that the energy leaks out into the surrounding frequencies.

Figure 8. Sine spectrum with no leakage.

Figure 9. Sine spectrum with significant leakage.

Uniform Window (Rectangular)

w (k) = 1

Uniform is the same as no window function.

Hann Window

Flattop Window

The term "Hanning window" is sometimes used to refer to the Hann window, but is ambiguous as it is easily confused with Hamming window.

If a measurement can be made so that no leakage effect will occur, then do not apply any window (in the software, select Uniform.). As discussed before, this only occurs when the time capture is long enough to cover the whole transient range, or when the signal is exactly periodic in the time frame.

If the goal of the analysis is to discriminate two or multiple sine waves in the frequency domain, spectral resolution is very critical. For such application, choose a data window with very narrow main slope. Hanning is a good choice. In general, we recommend Hanning window in VDC applications.

When you are extremely sensitive to the accuracy of peak estimation at certain frequency, choose Flattop window. It will give you the best estimation for the frequency components measured at a rotating machine or reciprocating machine.

Averaging Techniques

Averaging is widely used in spectral measurements. It improves the measurement and analysis of signals that are purely random or mixed random and periodic. Averaged measurements can yield either higher signal-to-noise ratios or improved statistical accuracy.

Typically, three types of averaging methods are available in DSA products. They are:

Linear Averaging, Exponential Averaging, and Peak-Hold

Linear Averaging

In linear averaging, each set of data (a record) contributes equally to the average. The value at any point in the linear average in given by the equation:

Averaged = Sum of Records/N

N is the total number of the records. The advantage of this averaging method is that it is faster to compute and the result is un-biased. However, this method is suitable only for analyzing short signal records or stationary signals, since the average tends to stabilize. The contribution of new records eventually will cease to change the value of the average.

Usually, a target average number is defined. The algorithm is made so that before the target average number reaches, the process can be stopped and the averaged result can still be used.

When the specified target averaging number is reached, the instrument usually will stop the acquisition and wait for the instruction for another collection of data acquisition.

Section 3

Exponential Averaging

In exponential averaging, records do not contribute equally to the average. A new record is weighted more heavily than old ones. The value at any point in the exponential average is given by:

y[n]= y[n-1] *(1-α)+ x[n]* α

where y[n] is the nth average and x[n] is the nth new record. a is the weighting coefficient. Usually a is defined as 1/(Number of Averaging). For example in the instrument, if the Number of Averaging is set to 3 and the averaging type is selected as exponential averaging, then α = 1/3.

The advantage of this averaging method is that it can be used indefinitely. That is, the average will not converge to some value and stay there, as is the case with linear averaging. The average will dynamically respond to the influence of new records and gradually ignore the effects of old records.

Exponential averaging simulates the analog filter smoothing process. It will not reset when a specified averaging number is reached.

The drawback of the exponential averaging is that a large value may embed too much memory into the average result. If there is a transient large value as input, it may take a long time for y[n] to decay. On the contrary, the contribution of small input value of x[n] will have little impact to the averaged output. Therefore, exponential average fits a stable signal better than a signal with large fluctuations.

Peak-Hold

This method, technically speaking, does not involve averaging in the strict sense of the word. Instead, the "average" produced by the peak hold method produces a record that at any point represents the maximum envelope among all the component records. The equation for a peak-hold is

Peak-hold is useful for maintaining a record of the highest value attained at each point throughout the sequence of ensembles. Peak-Hold is not a linear math operation therefore it should be used carefully. It is acceptable to use Peak-Hold in auto-power spectrum measurement but you would not get meaningful results for FRF or Coherence measurement using Peak-Hold.

Peak-hold averaging will reset after a specified averaging number is reached.

Overlap Processing

To increase the speed of spectral calculation, overlap processing can be used to reduce the measurement time. The diagram below shows how the overlap is realized.

Figure 10. Illustration of overlap processing.

As shown in this picture, when a frame of new data is acquired after passing the Acquisition Mode control, only a portion of the new data will be used. Overlap calculation will speed up the calculation with the same target average number. The percentage of overlap is called overlap ratio. 25% overlap means 25% of the old data will be used for each spectral processing. 0% overlap means that no old data will be reused.

Overlap processing can improve the accuracy of spectral estimation. This is because when a data window is applied, some useful information is attenuated by the data window on two ends of each block. However, it is not true that the higher the overlap ratio the higher the spectral estimation accuracy. For Hanning window, when the overlap ratio is more than 50%, the estimation accuracy of the spectra will not be improved.

Another advantage to apply overlap processing is that it helps to update the display more quickly.

Built-In Digital Integration And Filtering

Introduction to Digital Integration

Ideally, a measurement is made using a sensor that directly measures the desired quantity. For example an accelerometer should be used to measure acceleration, a laser velocimeter or velocity pickup should be used to measure velocity and a linear voltage displacement transducer (LVDT) should be used to measure position. However since position, velocity and acceleration are related by the time derivatives it is possible to measure an acceleration signal and then compute the velocity and position by mathematical integration. Alternatively you can measure position and compute velocity and acceleration by differentiating. The integration can be performed at the analog hardware level or at the digital level.

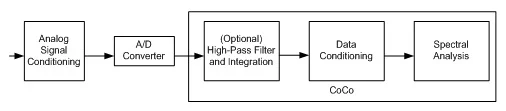

The CoCo provides a means to digitally integrate or double integrate the incoming signals. The integration module fits into the very first stage after data is digitized, as shown below:

Figure 11: Signal Processing Sequence in CoCo

There are several issues to address in such implementation:

The integration and double integration algorithm has to be accurate enough and it must find a way to reduce the effects of a DC offset. A tiny initial value, offset in the measurement or temperature drift before the integration, may result in a huge value after single or double integration. This DC effect can be removed using a high-pass filter.

The initial digital signal must have a high signal to noise ration and high dynamic range. The integration process in essence will reduce the high frequency energy and elevate the low frequency components. If the original signals do not have good signal to noise ratio and dynamic range, the signals after integration and double integration will have too much noise to use. The noise will corrupt the integrated signal.

The instrument must be able to set two different engineering units: one engineering unit for the input transducer and a second engineering unit after the integration. For example, first the instrument must provide a means to set the sensitivity of the sensor, say 100mV/g in acceleration. After the double integration the instrument must have the means to set the engineering unit to a unit that is compatible with the integration such as mm of displacement.

The CoCo instrument handles these three issues effectively so you can get reliable velocity or displacement signals from the acceleration measurement, or displacement signals from the velocity measurement. The CoCo hardware has a unique design to provide 130dB dynamic range in its front-end measurement. The signals with high dynamic range will create better results after digital integration.

Since such built-in integration is conducted in the time domain before any other data conditioning or spectral analysis, the time streams generated after the digital integration can be treated in the same way as other time streams. They can be analyzed or recorded.

CoCo also provides differentiation and double differentiation to calculate the acceleration or velocity from velocity or displacement transducers. Differentiation is not as commonly used as integration.

It must be noticed that the displacement value derived after double integration of the acceleration signal is not the same as that directly measured by a proximity probe. A proximity probe measures the relative displacement between a moving object (such as a rotor shaft) to the fixed coordinates seated by the probe (mounted to the case). The accelerometer and its integration value can only measure the movement of the moving object against the gravity field.

Sensor Considerations

Accelerometer signals that are non-dynamic, non-vibratory, static or quasi-static in nature (low acceleration of an automobile or flight path of a rocket) are typically integrated in the digital domain, downstream of the signal conditioner. Piezoelectric and IEPE accelerometers are commonly used to measure dynamic acceleration and, therefore, dynamic velocity and displacement. They should not be used to measure static or quasi-static accelerations, velocities, or displacements because the IEPE includes analog high pass filtering in the sensor conditioning that cuts out any low frequency signal. At low frequencies approaching 0 Hz, piezoelectric and IEPE accelerometers cannot, with the accuracy required for integration, represent the low frequency accelerations of a test article.

When this slight inaccuracy is integrated in order to determine velocity and displacement, it becomes quite large. As a result, the velocity and displacement data are grossly inaccurate. A piezoresistive or variable-capacitance accelerometer is a better choice for low frequency signals and for integration. These types of sensors measure acceleration accurately at frequencies approaching 0 Hz. Therefore the integration calculation of velocity and position can be used to produce accurate results.

Calculation Errors in Digital Integration

Two types of calculation errors can be introduced by parameters chosen for digital integration: low sampling rate and DC offset.

The sampling rate of a signal must be high enough so that the digital signal can accurately depict the analog signal shape. According to the Nyquist sampling theorem as long as the sampling speed is more than twice of the frequency content of the signals before the integration, the integration results should be acceptable. This is not true. Satisfying the Nyquist frequency only ensures an accurate estimate of the highest detectable frequency of a measurement. It will not provide an accurate representation of the signal shape. Integration error can still occur of a signal is sampled at more than twice the signal frequency. The figure below shows a 1kHz sine wave sampled at 8kHz and 5.12kHz.

Figure 12. A 1 kHz sine wave sampled at 8 kHz (top) and also sampled at 5.12 kHz (bottom).

It is clear that the higher the sampling frequency, the closer this digitized signal is to the true analog waveform. When the sampling rate is low, the digital integration will have significant calculation error. For example the 5.12 kHz sampled signal is not symmetric about 0 volts so the integration will drift and a double integration may grow with accumulated error very fast.

In general, you should use a sampling rate at least 10 times higher than the frequency content that is of interest in the signal when you apply numerical integration. (For example, a motor at 3600 RPM is driving a machine through a gear box which has a 3:1 reduction gear with 36:12 gear teeth. To detect the gear mesh frequency, the motor speed of 60 Hz is multiplied by the number of teeth to get the gear mesh frequency of 2160 Hz. To detect problems in the gearbox it is necessary to sample at 2.16 kHz or higher.) Think of trying to draw a single sine wave using points on a graph. It will be much more clear with 10 points or more than with only two.

DC offset is the second type of digital integration error and can be more severe. It is caused by any measurement error before integration and may result in huge amplitude errors after the integration. The illustration below shows how a small measurement error in acceleration will create a constant DC offset in the acceleration integrated to compute velocity and result in a drift and eventually an infinitely large magnitude of displacement after double integration.

Figure 13. A small error in acceleration results in a DC offset in velocity and a huge drift in displacement.

Of course, the computed velocity and displacement signals are unrealistic. They are artifacts of the integration errors. In order to remove such a problem caused by inaccurate measurement and digital integration, a high pass filter can be applied before or after the integration. It should be noted that the high-pass filter will distort the waveform shape to some extent because it alters the low frequency content of the signal. However this effect must be tolerated if numerical integration is used.

Digital High-Pass Filter

The most effective way to remove the DC drift effect as described above is to apply a high pass digital filter to the continuous time streams. In CoCo, a unique algorithm is realized so that even the data is sampled at high rate, the high pass filter can still achieve very low cutoff frequency. The high pass filter parameter can be entered in the channel table.

Figure 14: CoCo Input Channel Setup Table

The filter cutoff frequency is specified at -3dB attenuation.

To remove unwanted signals at or near DC, please set up the cutoff frequency of the digital high-pass filter as high as possible as long as it won’t chop off useful frequency content of your interest.

To give an example, if you are not interested in any frequency less than 20Hz, then you can set the cutoff frequency to approximately 10Hz. With this setting, the amplitude attenuation at 20Hz will be less than 1dB. (Typically, the lowest frequency of interest on rotating machinery will be one half the running speed of the machine. If the high pass filter is set to one third the running speed, the half order vibration will still be detectable.)

Section 4

Readings in a Vibration Data CollectorReadings

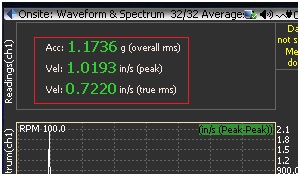

Readings are overall values that represent the characteristics of the measured signals. They are either calculated from time waveform or frequency spectrum. In CoCo these readings can be displayed individually or together with the waveform or spectrum.

Figure 15: Onsite Measurement Display

Peak and Peak-Peak

Peak and Peak-Peak values are calculated from the time waveform. Peak value is the largest signal level seen in a waveform over a period of time. For sine signals, the peak value is always 1.414 times the RMS value of the signal level. For non-sine signals, this formula will not apply.

The Peak-Peak value is the difference between the maximum and minimum signal levels over a period of time. For a pure sine wave, the Peak-Peak level is two times the peak signal level and 2.828 times the RMS value of the signal level. For a non-sine signal this formula will not apply.

Figure 16: Illustration of Time Domain Peak, Peak-Peak

If accelerometer is used and the Peak or Peak-Peak reading is displayed for velocity or displacement, the digital integration will be applied to the time waveform continuously before the Peak or Peak-Peak detection.

Overall RMS

In CoCo, the overall RMS is calculated based on the spectrum in frequency domain across all of the effective frequency range, i.e, from DC to maximum analysis frequency range.

Where:

BW = noise power bandwidth of window

Fa = analysis frequency band

Fs = sampling frequency band

0.45 = the ratio of Fa/

According to “Parseval's theorem”, such overall RMS is equivalent to that calculated in the time domain.

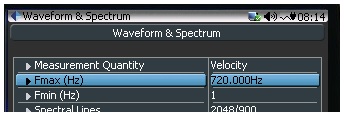

True RMS

In CoCo, the true RMS is calculated based on the spectrum in frequency domain between Fmin and Fmax.

Where:

BW = noise power bandwidth of window

Fmax = maximum frequency of interest

Fmin = minimum frequency of interest

Fmax and Fmin are set in the Analysis Parameters in CoCo. They control the maximum and minimum frequency of interest, as shown below:

Figure 17: CoCo Display, Setting Fmax

Obviously, the true RMS will be no greater than the Overall RMS.

Demodulation Spectrum

A useful technique for measuring and analyzing data is a process called Demodulation. The demodulation process is effective for detection of high frequency low amplitude repetitive patterns that lie embedded within the time waveform. These are characteristic of certain types of mechanical faults, particularly rolling element bearing faults such as inner or outer race cracks and spalls that make a clicking or ringing tone as the rolling elements pass over the fault. Demodulation is useful as an early warning device, as it detects bearing tones before they are visible in a normal spectrum. As the fault progresses towards failure, the frequencies will spread out and appear more as an increase in the “noise floor” of the FFT spectrum as the amplitude increases.

The process works by extracting the low amplitude, high frequency impact signals and then tracing an 'envelope' around these signals to identify them as repetitions of the same fault. The resulting spectrum, with the low frequency data removed, will now clearly show the high frequency impact signals and harmonics.

The high frequency signals that demodulation aims to extract are do not travel well through large structures, therefore extra care must be taken to ensure the accelerometer is setup correctly. Ensure that:

The accelerometer is mounted close to the fault source with the shortest direct path through the structure to the accelerometer.

The accelerometer is well coupled, using either stud mounting or a very strong magnet on bare metal. A handheld probe or stinger is not recommended.

The accelerometer mounting is consistent between visits. If not, a trend plot of overall RMS values will be meaningless.

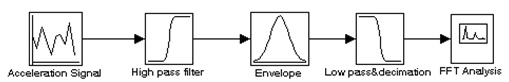

The demodulation process can be graphically described in the following flow chart:

Figure 18: Demodulation Process Flow Chart

Below is a depiction of an acceleration time waveform with a repetitive high frequency component. Because of the large difference in amplitude and frequency, a very low amplitude high frequency signal could be overlooked during routine vibration analysis.

Figure 19: Acceleration Time Waveform with Fault

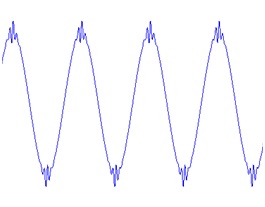

The high-pass filter removes the low frequency component of the signal, below:

Figure 20: Acceleration Time Waveform after High Pass Filter

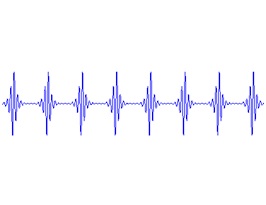

The next step in the process is enveloping which lowers the frequency of the signal to that of the repetitive element.

Figure 21: Signal after Enveloping

The final step is to process the resulting time waveform signal into a frequency spectrum. Since the signal has been altered by removal of low frequencies and enveloping, it is referred to as the Demodulated Spectrum.

Figure 22: Demodulated Spectrum

A Bearing Detection Example of Demodulation

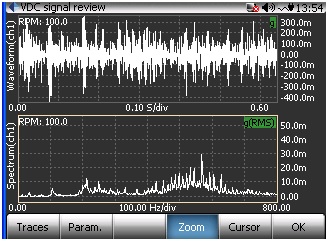

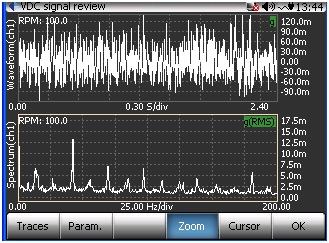

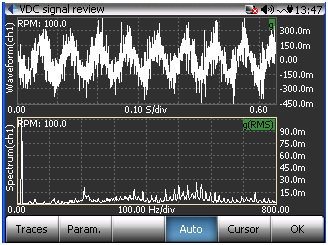

The following examples show CoCo screens in VDC mode being used to analyze a rolling element bearing with a slight defect.

Figure 23: CH1 Time Waveform and FFT with slight bearing defect

The following is the same signal with the demodulation spectrum on the lower trace:

Figure 24: CH1 Time Waveform and Demodulation Spectrum with slight bearing defect

As the bearing deteriorates, the defect typically becomes larger and generates a wider range of frequencies as the rolling elements pass over it. The following is the demodulation spectrum with slightly deteriorated bearing:

Figure 25: CH1 Time Waveform and Demodulation Spectrum with slightly deteriorated bearing

As can be seen in the screen below, the standard FFT spectrum shows the relatively high first order amplitude but only shows an elevated noise floor in the higher frequencies.

Figure 26: CH1 Time Waveform and FFT Spectrum with deteriorated bearing

Section 5

Using Accelerometers and TachometerAccelerometers for Industrial Applications

Accelerometers are widely used in the vibration data collection. By using the feature of CoCo’s very high dynamic range (130dB), the acceleration signals can also be accurately integrated into velocity and displacement signals. There are a wide range of accelerometers to choose in the market. Many of them are IEPE mode. In most of applications we recommend using IEPE accelerometers.

There are three types of accelerometers in the market: (1). accelerometers used for cost-sensitive market such as PDAs, electronic toys, automotive airbags or laptop computers. These are MEMS based sensors that cost a few dollars each. They do not fall into our categories. (2). The accelerometers used for testing and measurement purpose. The US manufacturers like PCB, Endevco and Dytran all focus on such applications; (3). The accelerometers used for machine vibration, or called industrial applications. US manufacturers include Wilcoxon, CTC and so on. Most often, the vibration data collector asks for the sensors from the last category. These sensors are relatively large in size, rugged, less accurate and less expensive than those from the category (2).

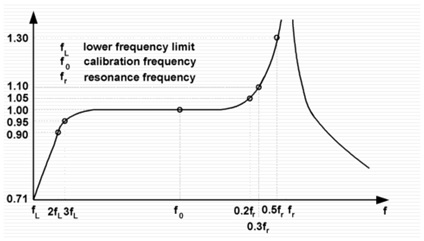

Mounting AccelerometersCare must be taken to insure the appropriate accuracy across the whole frequency range. The accuracy of your high frequency response is directly affected by the mounting technique that you select for the sensor. In general, the greater the mounted surface area contact between the sensor and the machine surface, the more accurate your high frequency response will be. High frequency response is based on the sensor specified as well as the method of attachment together with a system. Stud mounted sensors are often able to utilize the entire frequency range that the sensor specified. Conversely, a probe tip mounted sensor has very little surface area contact with the machine surface, and offers very little high frequency accuracy above 500Hz (30, 000CPM).

The picture below shows the frequency response of a typical accelerometer. It might be surprising to you that how inaccurate the measurement can be at different frequency range.

Figure 27: Frequency Response of a Typical Accelerometer

The following chart offers a general guideline for the range of mounting techniques available, and the corresponding high frequency response expectations.

Figure 28: Accelerometer Mounting vs Maximum Frequency Response

Choose the Sensitivity

The user must pay attention to the sensitivity of the sensor when they source it. Select an accelerometer by matching its output for expected acceleration levels. Don’t “crowd” the full-scale specifications. Allow a margin for unexpectedly large accelerations. Using only the lower 20% of an accelerometer’s response range will ensure ample margins for unpredicted overloads. After you select an accelerometer that can survive predicted worst-case shock limits, compute the sensor’s output voltage. At a sensitivity of 10 mV/g, for example, an accelerometer that encounters a 100-g shock will produce a 1-V peak signal. This is well wthin the +/-10V range of CoCo input channels. However it must be noted that this definition is accounted in the acceleration domain. To transform the specification from the velocity domain, the frequency factor has to be accounted.

Integral Electronics Piezoelectric (IEPE) Sensor

IEPE accelerometers operate from a low-cost, constant-current power source over a two-wire circuit with signal/power carried over one wire and the other wire serving as ground. The cable can be ordinary coaxial or ribbon wire. Low-noise cable is not required. Constant current to operate the accelerometer comes from a separate power unit or it may be incorporated inside a readout instrument such as an FFT analyzer or Data Collector. Integrated electronic accelerometers are available under several different trademark names such as ICP® (PCB Piezotronics), Isotron® (Endevco), Delta-Tron® (B&K), and Piezotron® (Kistler) to mention a few. CoCo IEPE input mode provides 4.7mA constant current for each channel.

The main advantage of low-impedance operation is the capability of IEPE accelerometers to operate continuously in adverse environments, through long, ordinary, coaxial cables, without increase in noise or loss of resolution. Cost per channel is less, since low-noise cable and charge amplifiers are not required. The main limitation involves operation at elevated temperatures, above 325 °F.

The signal conditioning circuitry in the instrument box usually has high-pass and low-pass filter. When IEPE is selected in the CoCo, the high-pass filter cutoff frequency is set fixed at 0.3 Hz @ (-3dB) and 0.7 Hz @ (-0.1dB).

IEPE sensor will not be able to measure the DC or quasi-constant acceleration signal. This is usually not a problem to the acceleration measurement because in our world, no objects can keep moving at constant acceleration.

Tachometer

Tachometer is used to measure the rotating speed of the rotating machines. There are many kinds of tachometers that can be chosen for CoCo. In general, as long as the tachometer claims that it output analog pulse signal, it will be able to interface to the CoCo input channel.

The first analog input channel can be configured as a tachometer measurement. Threshold -10V~ +10V user selectable. This tacho channel accepts either the tacho sensor with regular voltage output or a tacho sensor with IEPE/ICP interface.

Typical tacho measurement specification using a PLT200 tachometer from Monarch Instrument is:

RPM Range: 5~200,000 RPM

Accuracy: ±0.01% of reading

Resolution: 0.001 to 10 RPM

Operating Range: 2 inches to 25 feet

Figure 29: Monarch PLT200 Tachometer

Pocket Laser Tachometer 200 Kit includes: Tachometer, Remote Contact Assembly (RCA), Carrying Case, Factory Calibration Certificate and 5 ft roll of T-5 reflective tape. PLT200 has a TTL compatible Pulse Output that can be connected to the channel 1 of CoCo.

Typical Connections of CoCo with Accelerometers and Tachometer

Several typical connections are recommended below using a four channel CoCo device. If you are doing the route data collection, make the same parameter setup in EDM, upload the route to the CoCo and conduct the test. This setup cannot be changed on CoCo.

If you are conducting onsite measurement, set the input channels accordingly in the Input Channel and Sensor setup on CoCo.

Case 1: Single Channel Vibration Measurement

This is the simplest measurement. Connect ch1 of CoCo to the sensor.

Figure 30: Connecting Channel 1 to Accelerometer

Case 2: Tri-axis Vibration Measurement

You can use either one tri-axis accelerometer to measure the 3D vibration. Simply connect ch1, ch2 and ch3 of CoCo to the X, Y and Z axis of the tri-axis sensor. The sensor will generate signals for three channels simultaneously.

Figure 31: Connecting Tri-axis Accelerometer

Case 3: Single Channel Vibration Measurement + Tacho

Connect ch1 of CoCo to the analog output of tachometer; connect ch2 of CoCo to the sensor.

Figure 32: Connecting Tachometer and Accelerometer

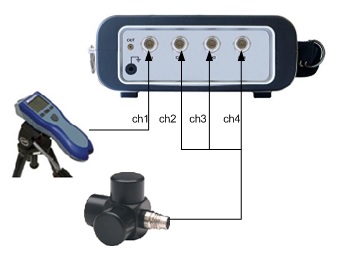

Case 4: Tri-axis Vibration Measurement + Tacho

Connect ch1 of CoCo to the analog output of the tachometer. Connect ch2, ch3 and ch4 of CoCo to the X, Y and Z axis of the tri-axis sensor.

Figure 33: Connecting Tachometer and Tri-axis Accelerometer