Seamless Environmental Testing with Combined Test Procedure (CTP) in EDM 12.1

Environmental testing just became smarter and simpler. For engineers needing to verify performance against rigorous requirements, CTP ensures adherence to complex standards like MIL-STD-810H Method 520.5 Combined Environments. The new Combined Test Procedure (CTP) feature in EDM 12.1 allows users to synchronize temperature, humidity, and vibration testing in a single, unified workflow.

By connecting temperature and humidity chambers with vibration shaker systems, CTP enables fully automated, repeatable, and efficient testing — all managed through one intuitive interface.

All-in-One Control for Complex Tests

CTP is designed to orchestrate multiple pieces of test equipment, ensuring every component works in harmony.

Users can now run a temperature and humidity profile while executing multiple vibration tests, following industry standards or replicating real-world operating conditions.

Future updates will extend CTP’s capabilities to include water chillers, charge cabinets, and more, expanding the scope of combined environmental testing.

“EDM 12.1 Combined Test Procedure orchestrates multiple instruments for synchronized environmental testing.”

Visualizing Synergistic Test Profiles for MIL-STD-810 Compliance

CTP is designed to handle the complex, sequential requirements necessary for demonstrating compliance with rigorous standards such as MIL-STD-810H, Method 520.5. This method is critical because it focuses on evaluating the synergistic effects of combined environmental stresses. These complex environments can include combinations of temperature, altitude, humidity, input electrical power, and vibration, and their synergistic application may induce failures that would not be exhibited during individual environment testing.

The diagram below, adapted from the MIL-STD-810H Method 520.5 specification (specifically Figure 520.5-1, the Test Profile Generation Flow Diagram), illustrates the methodical steps required (Step 1 through Step 9) to derive representative combined environmental test profiles from initial mission and platform requirements. This visualization demonstrates how environmental stresses (including Temperature, Humidity, Altitude, Vibration, Electrical/Operation, and Supplemental Cooling) are correlated with specific mission segments (e.g., Take-off, Cruise, Land) to create a highly traceable, combined test schedule. This systematic derivation process is essential for ensuring that the testing reflects the real-world Life Cycle Environmental Profile (LCEP) of the material.

The CTP schedule interface is designed to reflect the logic of the standard’s profile. By making the CTP schedule visually consistent with the combined profile illustrated in Figure 520.5-1, users can easily configure a complex schedule. This design helps users minimize setup time as they can visually compare the software configuration directly to the standard document, confirming that their setup accurately replicates the required synergistic test profile.

Clear, Centralized Test Overview

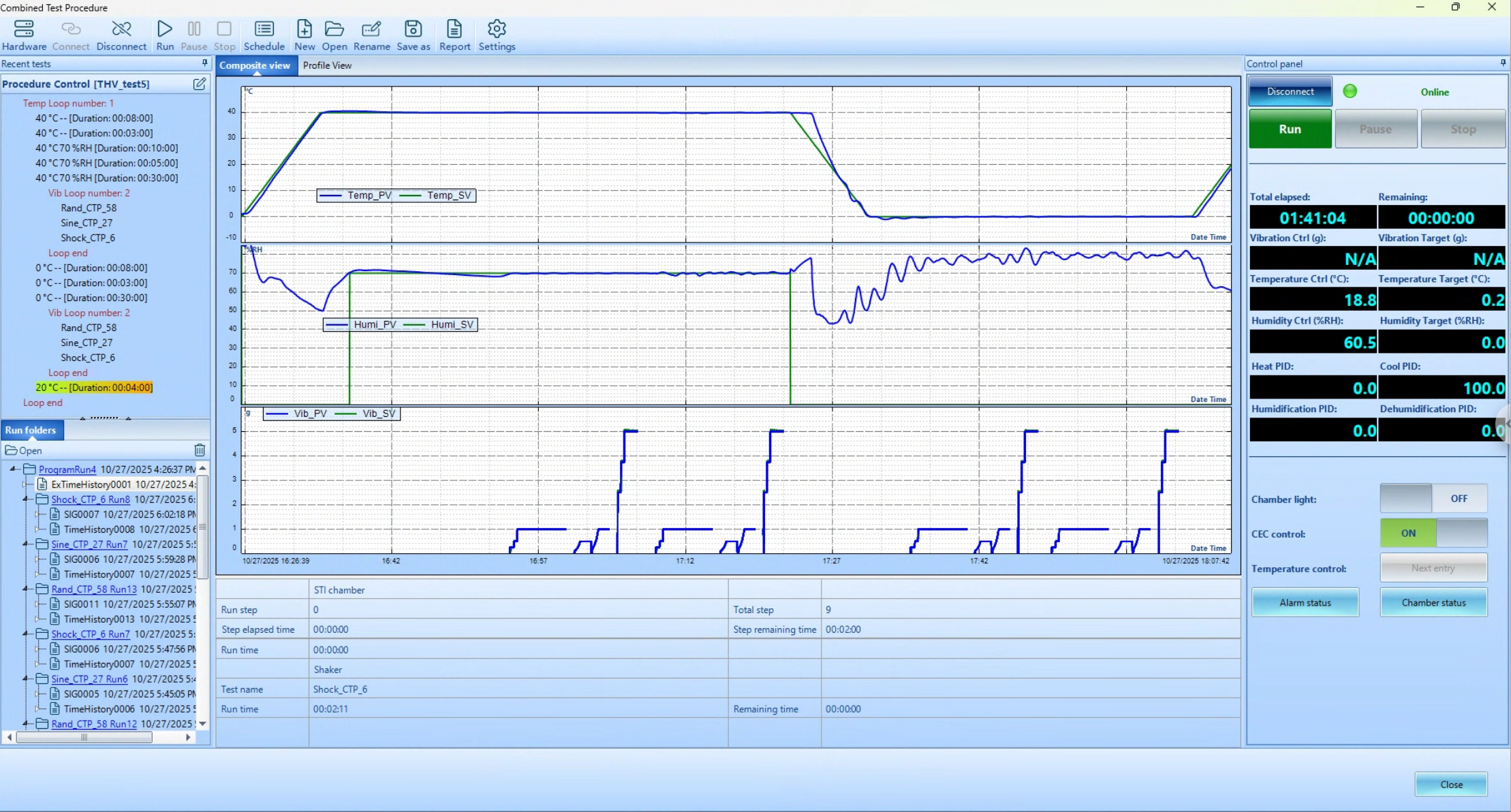

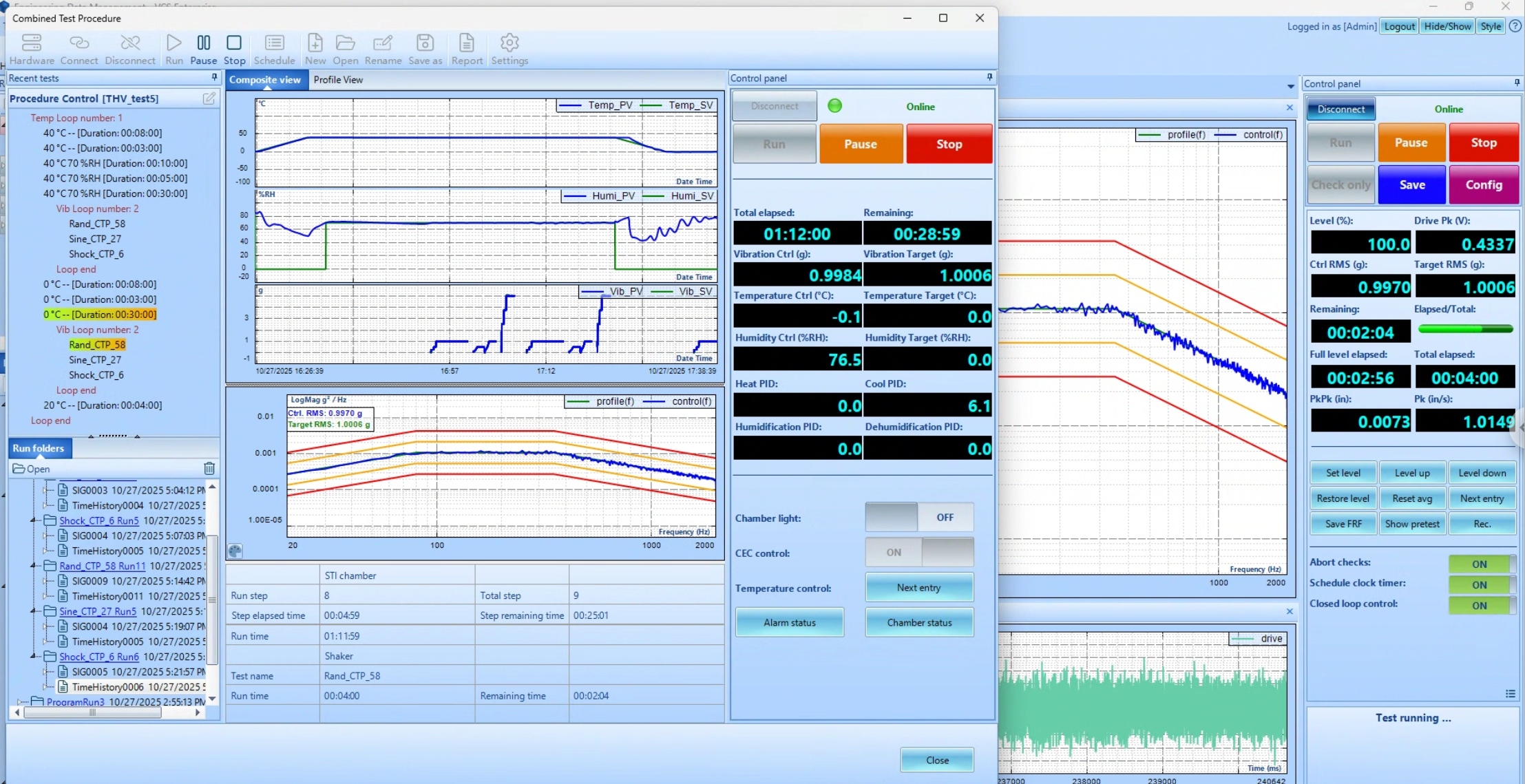

The CTP interface gives users complete visibility of the test environment:

Unified test dashboard – View and control all temperature, humidity, and vibration operations from one screen.

Real-time monitoring – Instantly compare target vs. actual values for all parameters to ensure precise control.

Live test status – Numeric indicators and active entry highlights show exactly where the system is in the test sequence.

Integrated data logging – Temperature, humidity, and vibration data are recorded and stored together for easy review.

This design ensures operators can quickly verify performance, minimize setup time, and maintain confidence in every test run.

“Centralized dashboard displaying real-time temperature, humidity, and vibration profiles during a combined test.”

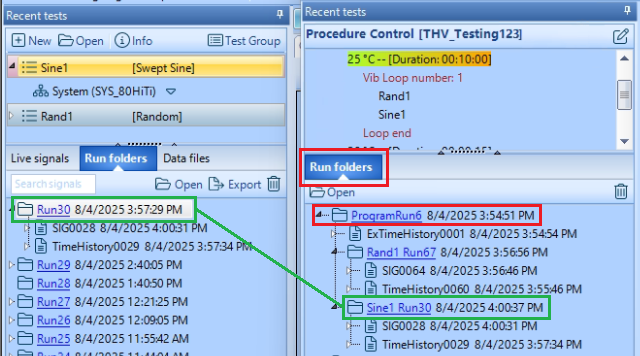

Simplified Data Management

All test data from the chamber and vibration controller are automatically stored in the same folder, making data organization straightforward.

This unified data structure eliminates confusion, speeds up post-test analysis, and simplifies report generation — ideal for long-term testing programs and compliance documentation.

“Unified data folder containing chamber and vibration controller results for seamless data management.”

Powerful Schedule Editing and Reporting

With CTP, creating and editing complex test schedules is effortless.

Users can define detailed sequences for temperature, humidity, and vibration, with full control over timing and ranges.

After the test, EDM automatically generates a comprehensive report combining all environmental and vibration data for complete traceability.

“Intuitive schedule editor for defining temperature, humidity, and vibration sequences within EDM 12.1.”

Dual Display for Environmental and Vibration Data

The Vibration Control Composite window is displayed directly below the Temperature and Humidity (THV) Composite view in the CTP dialog.

This side-by-side visualization lets users see both test environments simultaneously, improving situational awareness and operational efficiency.

“Side-by-side THV and vibration composite views provide a clear overview of combined test performance.”

A Smarter Way to Test

The Combined Test Procedure marks a major step forward in environmental and reliability testing.

By merging multiple control systems into a single cohesive workflow, EDM 12.1 empowers engineers to run complex tests with greater accuracy, consistency, and ease.

Whether for automotive, aerospace, electronics, or energy applications, CTP ensures that your testing reflects the real-world conditions your products will face — all while saving time and reducing complexity.

To learn more about Combined Test Procedure:

International users: https://www.crystalinstruments.com/international-distributors