Santa Clara, CA - November 25, 2025 — Crystal Instruments Corporation, a global leader in vibration testing, dynamic measurement, and data acquisition technologies, today announced that the United States Patent and Trademark Office has officially granted U.S. Patent No. 12,483,216 B2, titled “Data Recording Based on Dual ADC Architecture.” The patent is credited to inventor James Q. Zhuge, founder and CEO of Crystal Instruments.

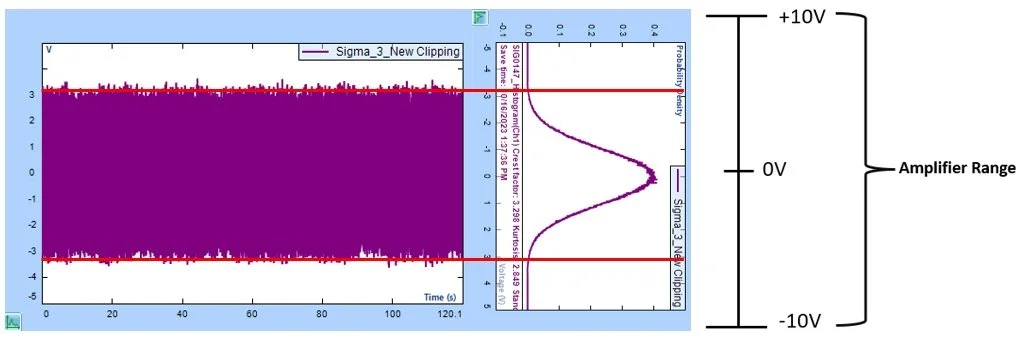

Read MoreWhy Sigma Clipping?

This feature prevents amplifiers from tripping when the input ranges of an amplifier are lesser than the drive signal required to achieve a target GRMS.

The Fatigue Damage Spectrum (FDS) serves as a pivotal tool in the assessment of structural integrity, portraying the relationship between damage and natural frequency across the frequency domain. Its utility extends to testing laboratories, empowering them to craft precise Random vibration test profiles by analyzing acceleration vibration data derived from real-world environments. By using the FDS, these labs can accurately delineate the damage experienced by structures under dynamic loads, facilitating the development of robust testing protocols essential for ensuring product reliability and safety.

Read MoreThe case described in this article examines the modal characteristics of a satellite model acquired from performing experimental modal analysis. A hammer impact test was carried out with two teardrop uni-axial accelerometers (mounted in different directions) to study the modal behavior. The roving excitation method assists in completely avoiding the potential mass loading side effect produced by a roving response procedure. A hard tip was selected to excite the higher frequency modes.

Read MoreShaker applications involve the use of many attachments to the shaker’s armature. Head expanders, fixtures, adapters, and devices under test (DUT’s), all attach to the shaker for the testing process. While it is common to simply consider the added mass of these components, their deformation during vibration can also have a significant impact on the vibrations experienced at any certain point of interest.

Read MoreCrystal Instruments is excited to announce the release of our new VCS software module, Blade Fatigue Testing (BFT). Fatigue testing of blades is a critical step in mechanical design, whether it be turbine, compressor, or even propeller blades.

Read MoreVCS includes a full range of functions to create/run tests, calculate signals, and analyze/report/export data. Some users may not require all these tests and may prefer a lighter, more signal focused experience. These users can now use our new software program, Signal Viewer.

Read MoreOur team is thrilled to announce the 11.1 version of Engineering Data Management (EDM) software. Packed with a range of new features and improvements, this update is designed to elevate the user experience.

Read MoreCrystal Instruments Multi-Exciter Single- Axis (MESA) vibration test control allows users to closely replicate real-world applications according to the complex and multi-DOF nature of real vibrations. MESA vibration testing is most commonly used with higher forces on each axis and with long vertical dimensional testing units. Crystal Instruments provides the highest quality and technologically advanced solutions for MESA vibration testing and recently provided comprehensive MESA testing on a dual 300 KN shaker system at an industrial environmental testing lab.

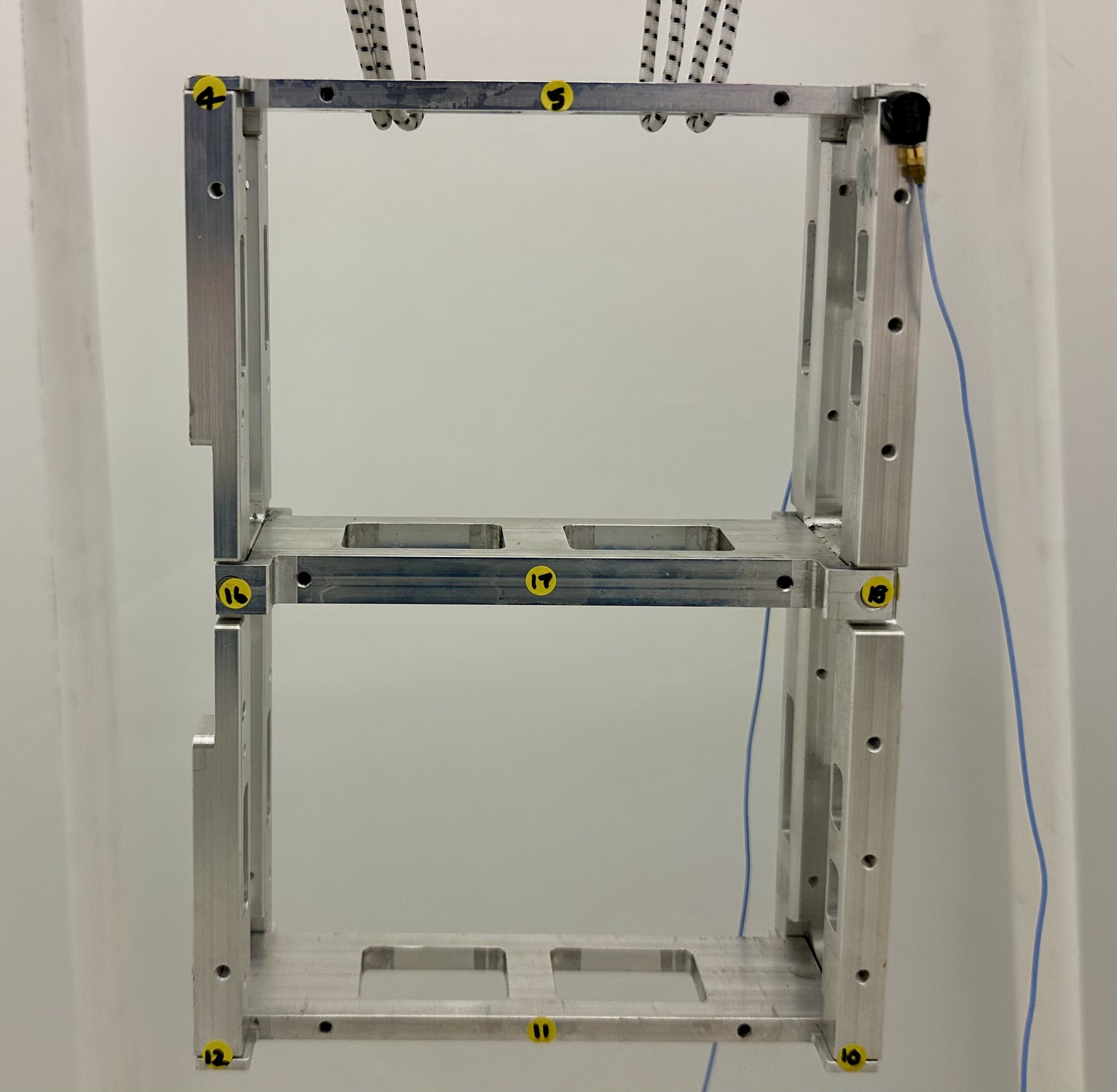

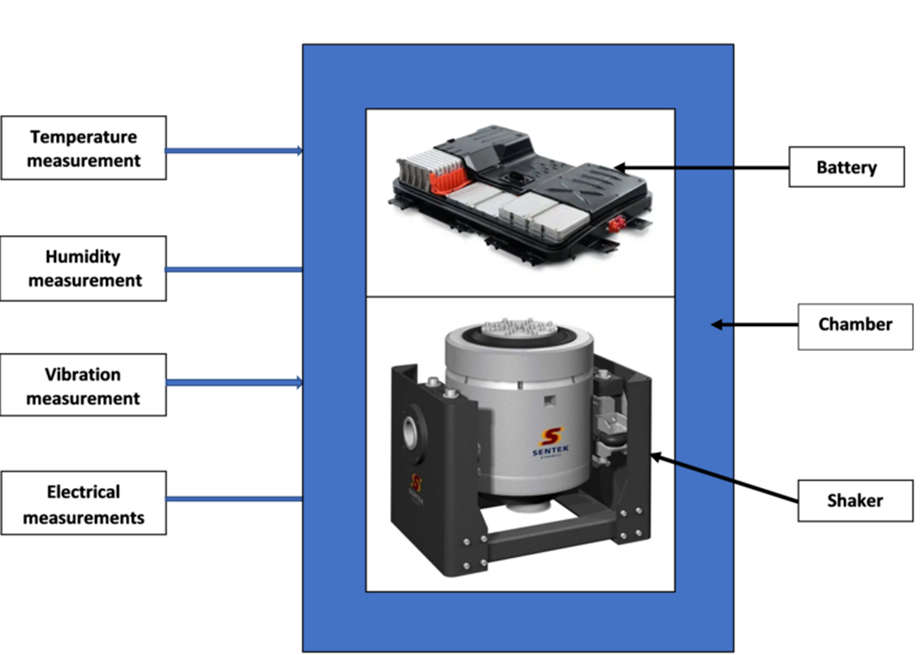

Read MoreIn the evolving world of transportation, Electric Vehicles (EV) have become a superior choice for consumers, resulting in a rising demand for automobile manufactures to produce safe, reliable, and efficient EV’s. Along with the higher production volume comes rigorous standards for testing, specifically when it comes to the crucial components, such as battery packs.

Read MoreUsers can monitor the status of environmental tests (vibration, temperature, humidity) operating in EDM VCS, measurements taken in EDM DSA, and remotely located tests by implementing MQTT in EDM.

Read MoreWatch our new Ground Vibration Testing video with narration by Walter Kemphaus, Product Manager. To learn more about Ground Vibration Testing, visit: https://www.crystalinstruments.com/ground-vibration-test

Read MoreThe new Transducer Calibration Software helps ensure accurate vibration test measurements by simplifying the calibration process, saving time, and confirming that measurements are performed within specifications.

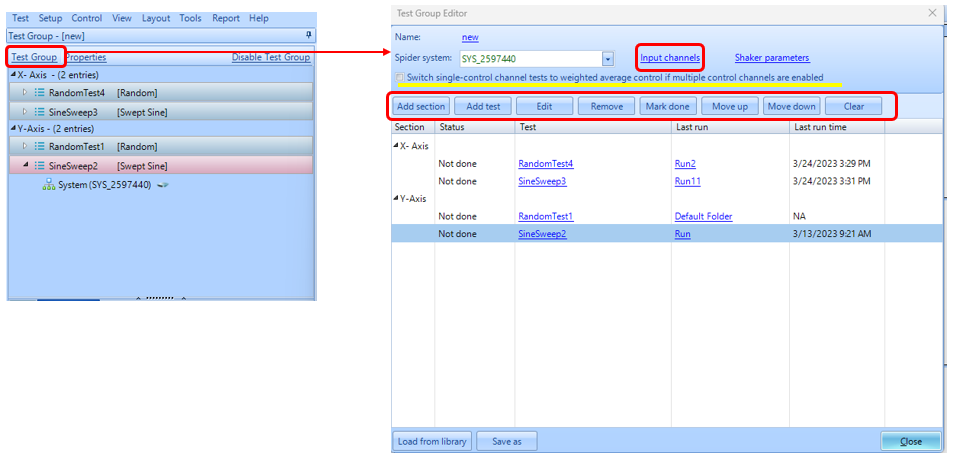

Read MoreThis article discusses a new EDM 11.0 release feature called Test Group, which organizes multiple tests into sections, to run in sequence, and shares test configurations. EDM allows users to configure and re-use the same test for the same or different objects. All configurations and test parameters are applied to a single test. Settings can be loaded and applied to a new test from a saved library. Test configurations are easily shared by sharing just the test file.

Read MoreUpdated signal display features in Engineering Data Management (EDM) software, version 11.0 allows users to quickly add many signals in stack plots and individual plots.

Read More